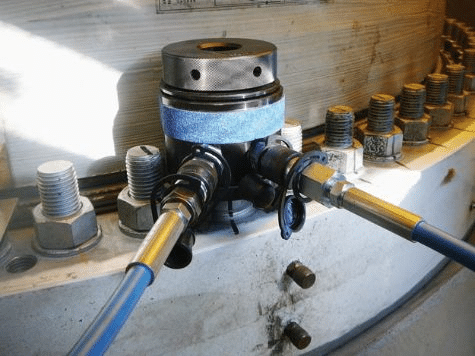

Hydraulic bolt tensioners are essential in industries where precise tightening of bolts is critical to maintain structural integrity and safety. From wind turbines to industrial equipment, these tools serve a pivotal role. However, like any machinery, they can encounter issues over time. At Northern Lights Solutions (NLS), we specialize in servicing hydraulic bolt tensioners, ensuring your equipment stays in optimal condition. Understanding the common problems that arise and how to address them can save you time, money, and unnecessary downtime.

The Role of Hydraulic Bolt Tensioners

Hydraulic bolt tensioners create controlled tension in bolts, which helps eliminate inaccuracies associated with manual tightening methods. They are critical in high-stakes industries like energy, construction, railroads, and heavy machinery. With proper use, they ensure the right clamping forces, enhancing reliability and preventing equipment failure.

However, the effectiveness of these tools depends on their maintenance. When neglected, they can lead to performance degradation, costly repairs, or safety hazards. Below, we’ll highlight common issues with hydraulic bolt tensioners and provide actionable solutions to resolve them.

Common Issues and Solutions for Hydraulic Bolt Tensioners

1. Seal Leaks

Hydraulic bolt tensioners rely on high-pressure seals to maintain proper function. Over time, these seals can wear down due to repeated use or contamination.

Causes:

- Improper application.

- Exposure to dirt and debris.

- Excessive vibration

Signs of the Issue:

- Hydraulic fluid leakage.

- Reduced tensioner performance.

Solution:

Seal leaks require prompt repairs. At NLS, we provide expert hydraulic repair services to replace damaged seals and restore equipment efficiency. Regular maintenance and cleaning can also prevent premature seal failure.

2. Loss of Hydraulic Pressure

Hydraulic bolt tensioners demand consistent pressure to function effectively. A drop in hydraulic pressure can render the equipment ineffective and jeopardize safety.

Causes:

- Air in the hydraulic system.

- Damaged hoses or fittings.

- Faulty pressure pumps.

Signs of the Issue:

- Uneven bolt tensioning.

- Sluggish or incomplete pressurization.

Solution:

Check for visible damage to hoses and ensure fittings are tightly secured. At NLS, our skilled technicians can diagnose pressure issues using advanced diagnostic tools, providing full calibration and fixing pressure-related problems on-site or at our modern service center.

3. Cylinder Wear or Damage

Frequent use or improper handling can lead to cylinder wear or deformation, compromising the tensioner’s ability to apply consistent force.

Causes:

- Overuse or overloading.

- Improper storage.

- Corrosion from environmental factors.

Signs of the Issue:

- Reduced or uneven tensioning force.

- Visible cylinder damage.

Solution:

Inspect cylinders regularly for any signs of wear, cracks, or deformation. NLS provides professional hydraulic cylinder repairs, leveraging factory-authorized parts and precision tools to restore your equipment’s functionality.

4. Malfunctioning Hydraulic Pumps

The hydraulic pump is the heart of the system, and any failure can lead to a complete shutdown of operations.

Causes:

- Wear and tear from long-term use.

- Contaminated hydraulic fluid.

- Lack of proper lubrication.

Signs of the Issue:

- Pump overheating.

- Loss of pressure output.

- Difficulty starting the pump.

Solution:

Preventative maintenance is key. Ensure the hydraulic fluid is clean and replaced at regular intervals. At NLS, we offer hydraulic pump repair and replacement services, ensuring your system meets performance standards.

5. Corrosion and Rust

Exposure to moisture or harsh environments can accelerate corrosion, leading to material degradation and operational inefficiencies.

Causes:

- High humidity or water exposure.

- Neglected storage or cleaning practices.

Signs of the Issue:

- Rust on the housing or internal components.

- Sticking or difficulty moving parts.

Solution:

Store equipment in a clean, dry environment and apply corrosion-resistant coatings where necessary. For tools that are already affected, NLS offers part replacements to combat rust damage.

6. Improper Calibration

Calibration is critical to achieving accurate tensioning forces. Over time, bolts may become over-tightened or under-tightened if the tensioner isn’t precisely calibrated.

Causes:

- Misalignment of tools.

- Manual errors during setup.

- Long intervals between calibrations.

Signs of the Issue:

- Fluctuations in bolt tightness.

- Reduced structural integrity.

Solution:

Schedule regular calibrations to maintain tool accuracy. At NLS, we are certified to calibrate hydraulic tools to precise standards, offering services for tensioners and hydraulic wrenches up to 50,000 ft-lbs.

7. Contamination in Hydraulic Fluid

Clean hydraulic fluid is essential for smooth operation. Contaminants like dirt, water, or metal shavings can impair system performance.

Causes:

- Inefficient filtration.

- Poor maintenance practices.

- Contaminated replacement fluids.

Signs of the Issue:

- Slower operation.

- Increased wear on internal components.

Solution:

Regularly check and replace hydraulic fluid. NLS provides inspections and fluid analysis to ensure your system is free from harmful contaminants.

The Importance of Preventive Maintenance

Preventive maintenance is the simplest way to extend the lifespan of hydraulic bolt tensioners. Routine inspections, cleaning, and servicing minimize the likelihood of sudden breakdowns. Here are some key maintenance tips:

- Inspect Tools Regularly: Look for visible wear, leaks, or damage.

- Safeguard Against Contamination: Use clean fluids and seal components properly.

- Follow Manufacturer Guidelines: Adhere to proper usage instructions to reduce the risk of overloading or damage.

- Choose Certified Servicing: Work with specialists like NLS to perform thorough inspections, repairs, and calibrations.

How NLS Can Help

At Northern Lights Solutions, we focus on delivering expert hydraulic repair services tailored to your industry needs. Our capabilities include:

- Hydraulic Equipment Repair: From tensioners to pumps, we specialize in restoring functionality and performance.

- Certified Calibration Services: We calibrate hydraulic tools to precise specifications to ensure accuracy and reliability.

- Preventative Maintenance Programs: Reduce downtime and extend equipment lifespan with customized maintenance plans.

- On-Site Support: For larger tools and systems, we bring our expertise directly to your location with mobile inspection and calibration solutions.

- Factory-Authorized Parts and Repairs: We use genuine parts for longer-lasting repairs.

With a team of skilled technicians and a commitment to quick turnarounds, NLS is your partner in keeping critical equipment running strong.

Reducing Downtime with NLS

When hydraulic bolt tensioners malfunction, it can lead to delays and costly interruptions. Partnering with Northern Lights Solutions ensures that downtime is minimized. Our efficient quoting system, rental options, and same-day calibration services provide solutions that align with both your timeline and budget.

Why Choose NLS?

- Certified by top brands like Enerpac and Power Team.

- Factory-authorized service and repairs.

- Advanced facilities equipped for high-capacity jobs.

- Support for a wide range of industries, from wind energy to railroads.

Get Expert Support for Your Hydraulic Bolt Tensioners Today!

Hydraulic bolt tensioners are indispensable tools that require proper care and maintenance to perform at their best. By addressing issues such as seal leaks, pressure drops, and corrosion promptly, you can ensure long-term reliability and safety. At Northern Lights Solutions, we have the expertise and resources to keep your hydraulic equipment operating efficiently, reducing downtime and maximizing productivity.

Whether you need routine maintenance, emergency repairs, or precise calibrations, NLS is here to support your equipment needs. Reach out to us today for tailored solutions that keep you moving forward.